How to Conserve Cash with Expert Commercial Refrigerator Repair Solutions

How to Conserve Cash with Expert Commercial Refrigerator Repair Solutions

Blog Article

Fixing Commercial Refrigeration Fixing: Strategies for Quick and Effective Fixes

Understanding the typical issues that pester business refrigeration systems and having a toolkit of analysis methods at your disposal can make all the difference in swiftly determining and fixing problems. As we navigate with the ins and outs of repairing industrial refrigeration repair work, we will certainly uncover the crucial strategies for settling problems successfully, making sure that businesses can keep ideal cooling efficiency and decrease downtime.

Typical Commercial Refrigeration Problems

Commercial refrigeration systems typically run into a variety of operational problems that can disrupt their efficiency and efficiency. One prevalent concern is improper temperature level control, which can lead to food wasting and waste if not promptly resolved. This issue may come from issues with the thermostat, evaporator follower, or condenser coils, calling for detailed inspection to determine the source. Another typical concern is insufficient airflow, typically triggered by clogs in the vents or a malfunctioning fan. Poor airflow can cause temperature variances within the fridge or freezer, affecting the quality and safety and security of kept products.

Moreover, refrigerant leaks posture a considerable worry as they not only influence the air conditioning capacity of the system but additionally add to environmental damage. Spotting and repairing leakages without delay is critical to protect against additional damages and make sure conformity with guidelines. Additionally, filthy condenser coils can hinder warmth transfer, compeling the system to work harder and take in even more power. Routine cleaning and maintenance can help stop this concern and extend the life expectancy of the refrigeration system.

Diagnostic Devices and Methods

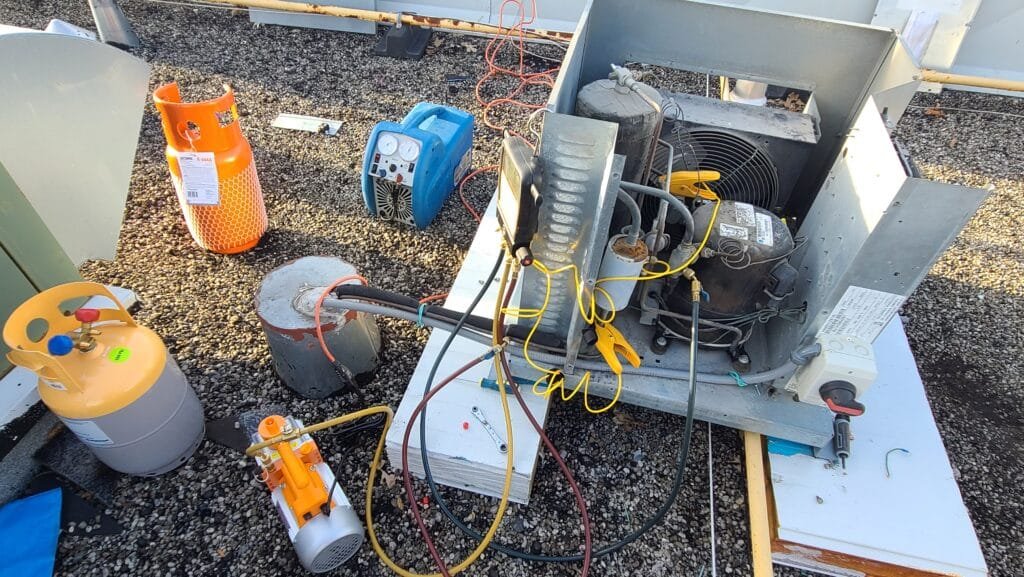

Reliable troubleshooting of industrial refrigeration systems counts heavily on utilizing specialized diagnostic tools and techniques to recognize and resolve underlying issues successfully - commercial refrigeration repair. Furthermore, leak detection tools like digital leak detectors or ultraviolet dye kits are crucial for situating refrigerant leakages that can lead to system inefficiencies.

Data loggers can be utilized to keep an eye on system performance over time and detect trends that might indicate reoccuring problems. By combining these diagnostic devices and techniques, technicians can efficiently troubleshoot industrial refrigeration systems and provide quick and specific repair work, lessening downtime and ensuring optimum system efficiency.

Quick Repairs for Refrigeration Problems

When confronted with refrigeration issues, service technicians can execute quick repairs to resolve typical concerns swiftly and effectively. One typical quick solution is examining for an unclean condenser coil, which can cause the system to run inefficiently. Cleansing the condenser coil regularly can improve the system's efficiency and avoid getting too hot. One more quick repair is guaranteeing that the refrigerator is not overloaded, as congestion can limit airflow and lead to temperature level inconsistencies. Readjusting the shelving to enable proper air blood circulation can often settle this issue. Furthermore, examining the door seals for any kind of indications of wear or damage and changing them if essential can assist maintain the honesty of the seal and protect against air leakages. Examining and readjusting the thermostat settings may supply a quick solution before more thorough troubleshooting is called for if the refrigeration device is not cooling down properly. By implementing these fast solutions, specialists can resolve usual refrigeration issues efficiently and maintain industrial refrigeration systems running efficiently. commercial refrigerator repair

Preventative Upkeep Tips

Applying a positive maintenance timetable is important for ensuring the durability and optimum performance of business refrigeration systems. Regular upkeep not just assists avoid expensive breakdowns however also guarantees that the devices operates successfully, saving power and minimizing general operating costs. Right here are some preventative maintenance ideas to keep commercial refrigeration systems running smoothly:

Inspect and Replace Filters: Filthy filters can limit air flow, making the system work more challenging and potentially creating damage. Inspect and replace filters regularly to protect against issues.

Inspect Seals and Gaskets: Dripping seals and gaskets can lead to temperature variations and energy waste. Inspecting and changing harmed seals can help keep constant temperature levels.

Professional Support and Solutions

To maintain the optimal performance accomplished via routine preventative upkeep, looking for expert support and services for industrial refrigeration systems is vital. Professional service technicians possess the know-how and specialized knowledge needed to diagnose and resolve intricate issues effectively. When facing tough refrigeration issues, relying upon expert support can conserve both time and cash in the future.

Specialist services provide advantages such as access to sophisticated devices and devices, making certain that repairs are executed properly. Furthermore, technicians are trained to adhere to market laws and security criteria, minimizing the danger of mishaps and making sure conformity with legal requirements.

Verdict

To conclude, fixing industrial refrigeration repair work needs a systematic method to determining usual problems, using diagnostic tools and strategies, carrying out quick solutions, and prioritizing preventative maintenance. Specialist assistance and services may be necessary for even more complex troubles - commercial refrigeration repair. By adhering to these methods, organizations can guarantee their refrigeration systems run effectively and properly, decreasing downtime and possible losses

Understanding the common concerns that torment commercial refrigeration systems and having a toolkit of analysis techniques at your disposal can make all the difference in swiftly identifying and remedying troubles.Reliable troubleshooting of business refrigeration systems relies greatly on using specialized diagnostic devices and methods to recognize and fix underlying concerns effectively. By incorporating these analysis tools and techniques, service technicians can properly repair commercial refrigeration systems and provide quick and precise fixings, lessening downtime and making certain optimal system efficiency.

By executing these quick solutions, specialists can attend to common refrigeration troubles effectively and keep commercial refrigeration systems running efficiently.

Additionally, expert support can help prolong the lifespan of business refrigeration systems by determining potential problems prior to they intensify.

Report this page